From start to finish,

we’ve got you sorted.

DC Sign Systems staff are committed to remaining at the forefront of our industry. At all times we will identify our clients needs and do our best to satisfy theses with the highest quality in design, production, and service.

To achieve these objectives we will continue to provide professional and friendly advise based on our 50 years of experience and innovation. Our future prosperity not only depends on our commitment to use of high-quality materials and workmanship but also to recognising the importance of our valued customers.

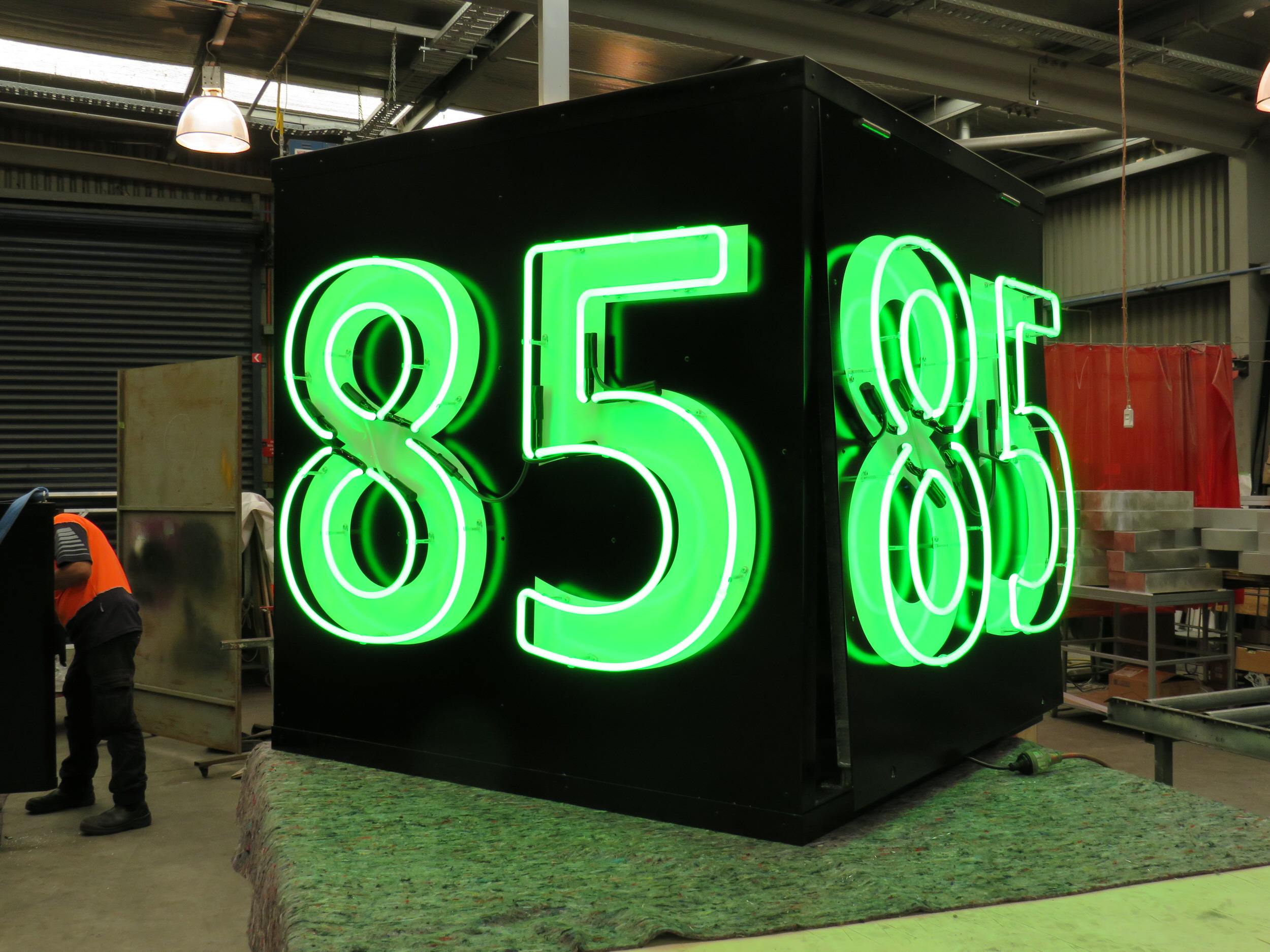

Some of our favourite work.

Trusted by these companies:

Delighting clients since 1969.

DC Sign Systems is a combination of expertise developed over 50 years from two of New Zealands premier signage companies: Deneefe Signing Systems Ltd and Corada Ltd.

In 2010 these companies combined resources and since then they have completed numerous local and nationwide projects to the absolute delight of our clients.